ARCTURUS

MODERN MISSLE DESIGN

SEARCH: LIBRARY of CONGRESS SUBJECT HEADINGS

TECHNOLOGY - T

- Missile - Map

- Missile - Types

- Missile - Titanium

- Missile - Propulsion

- Missile - Engineering

- Missile - Nose Cones

- Missile - Design Guide

- Missile - Solid Mechanics

- Missile - Design Concepts

- Missile - Structural Design

- Missile - Materials Science

- Missile - Tecnology Trends

- Missile - Structural Analysis

- Missile - Digital Manufacturing

- Missile - Tactical Missile Design

- Missile - Surface to Surface Design

- Missile - Automatic Control and Guidance

- Missile - Factory Architectural Design Plan

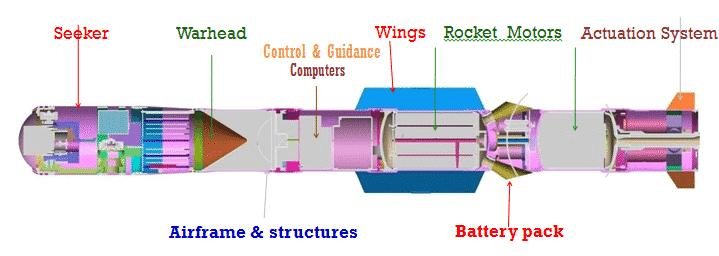

Missile structural engineering consists of a forward bodysection, a warhead bodysection, a rear body section, and several fins. Missiles have five system components: targeting, guidance system, flight system, engine and warhead . Missiles come in types adapted for different purposes: surface-to-air, surface-to-surface and air-to-surface missiles (ballistic, cruise, anti-ship, anti-tank, etc.), surface-to-air missiles (and anti-ballistic), air-to-air missiles, and anti-satellite weapons. Finally, missile testing, both developmental / operational is a continuous and evolutionary activity spanning the lifetime of the device.

SUBJECT EXPERTS I

SUBJECT EXPERTS II

SUBJECT EXPERTS III

RESEARCH GUIDES

DEFENSE SCIENCE JOURNAL

Program Development

The design / manufacturing process must be well understood at the macro level by the facility planning and engineering teams to ensure that an appropriate building concept is developed that is intergrated with manufacturing needs. Hiring a consultant(s) should be considered.

Design Aspects

The primary aspects of missile design are: Aerodynamics, Propulsion, Controls, Mass, and Structure. The various design aspects are joined together into a coherent whole. All missile design involves compromises of these factors to achieve the design mission.

Design Constraints

The design process starts with the missiles intended purpose. Hypersonic missiles are designed for stealth and quick strikes, while Intercontinental Ballistic Missiles (ICBM) are designed to destroy large human populations. Another key difference between the two is that hypersonic weapons remain in the atmosphere during flight, while ballistic missile / warheads spend much of their flight time in lower earth orbit.

Design Optimization

Hypersonic missiles and ICBM design projects are of such a large scale that every design aspect is supervised by different teams comprised of both engineers along with technicians and then amalgamated into an easily launched weapon system which is able to function under diverse meterological conditions.

Computer Designed Missile

Computer languages allow aeronautical engineers to write programs designed to enhance lethal efficiency along with optimizing nuclear payloads associated with many aspects of rocket science. Guidance technology translates electronic signals, which computers need to identify flight coordinates to successfully identify intended targets.

Design Process/Simulation

Missile conceptual design involves forming a variety of possible configurations that meet the desired design specifications. The design process is monitored by Missile Technology Control Regime (MTCR). Structural configurations must satisfactorily meet all the requirements of the aformentioned design aspects.