ARCTURUS

MODERN ROBOT DESIGN

SEARCH: LIBRARY of CONGRESS SUBJECT HEADINGS

TECHNOLOGY - T

SUBJECT EXPERTS I

SUBJECT EXPERTS II

RESEARCH GUIDES

NEWS: ROBOTICS

JOURNAL of ROBOTICS

Program Development

The design and manufacturing process of robotical engineering must be well understood at the macro/micro levels by the facility planning and engineering team(s) to ensure that an appropriate building concept is developed that is intergrated with schematic design criteria.

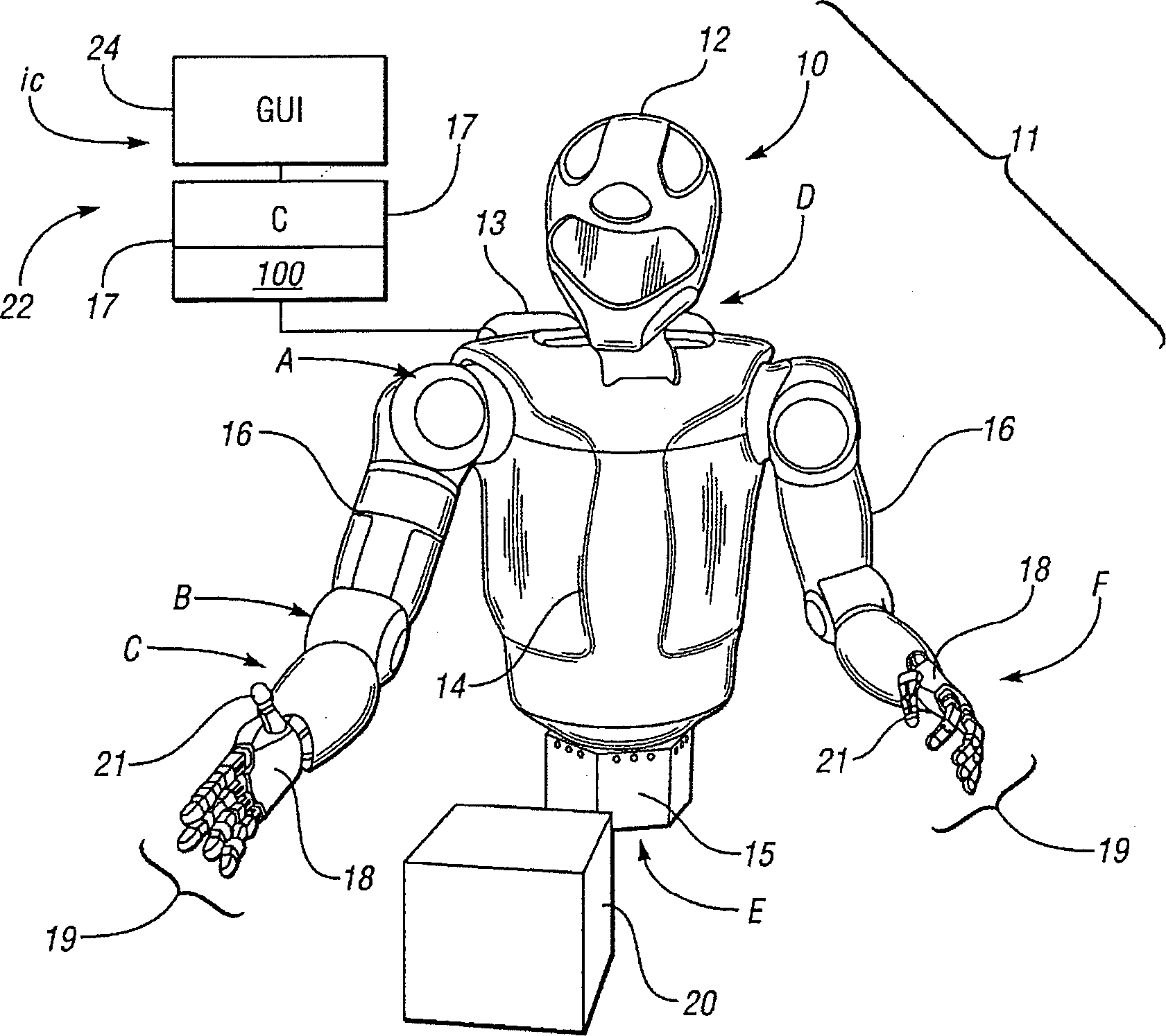

Design Aspects

The primary aspects of robot design are: environment, materials, power, senses, and style. In any particular case, design aspects vary because robots are capable of performing various functions through a broad range of applications.

Design Constraints

The design process starts with the robots intended purpose. Industrial robots are designed to perform repetitive tasks or engage in heavy lifting, while humanoid robots are are used in education, entertainment, healthcare, public relations, and search/rescue, etc.

Design Optimization

Optimized structural design for humanoid or industrial robots have to meet certain criteria regarding dimentional design and shape, material consumption and adapt this to the functional requirements. Topological optimization is a mathematical approach that allows engineers to identify the best concept design that meets structural requirements.

Software Design Robotics

Mechanical Engineers use Computer-Aided Manufacture (CAM) to design sophisticated robots. Computer Assisted Design (CAD) is capable of being scalable across multiple robotics applications, and be able to incorporate algorithms. Single software architecture, for both simulation and implementation, expedites the robotic design process.

Design Process/Simulation

Engineers will need to customize the robot setup within a given simulation. Some simulators make customization very simple while others make it very complex. A project team must identify a simulator that supports customization. It is likely to support many programming languages and be extended easily with plugins.